Setting a new standard in thread milling

GARANT Master TM solid carbide thread milling cutters - revolutionary in process reliability and performance

Perfection in thread milling.

Thanks to their unequal spacing of cutting edges, the new GARANT Master TM solid carbide thread milling cutters set new standards for thread milling. Due to their special innovative geometry the Garant Master TM achieves extremely smooth cutting and reduced cutting forces in the thread milling process.

These critical advantages lead to an extremely high degree of process capability combined with absolute process reliability. Whether in stainless steel, cast materials or high-tensile steels – thanks to their general-purpose characteristics the Garant Master TM family is always the right choice for your thread milling process.

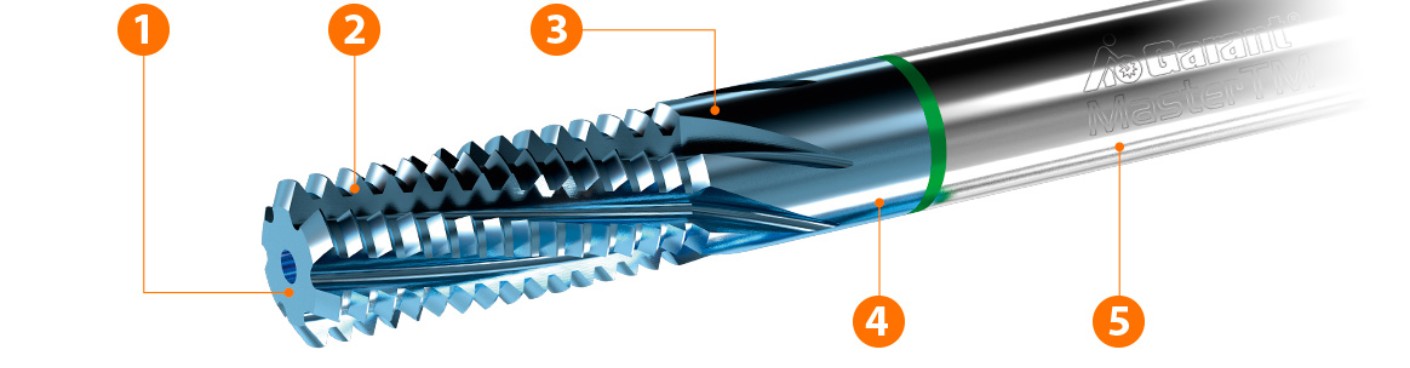

Special features

Always the right choice for your thread milling process:

- Unequal spacing: Significant reduction in vibration. Very smooth cutting action. Reduction in the cutting forces avoids tool displacement.

- Corrected thread profile: Avoidance of profile distortion. Threads true to gauge and true to standard.

- Innovative coating: The latest coating technology for optimum protection against wear. High performance over a wide spectrum of materials.

- Increased number of cutting edges: More efficiency due to increased contour feed rate.

- Optimised solid carbide substrate: Improved bending strength. High tool strength.

Measurable advantages in the production process

Very smooth cutting action and reduced cutting forces due to innovative geometry.

Radial cutting forces and vibration pose a major problem for the process reliability of the thread milling process. Thanks to their unequal spacing of cutting edges, GARANT Master TM solid carbide thread milling cutters significantly reduce these influencing factors, as cutting force measurement impressively demonstrates.

Measuring point A: after 180° cutter entry path at entry into the wall of the hole

The measurement points for GARANT Master TM show a well-defined distribution of the bending moment.

The comparison tools showed a visibly more uneven distribution, which is traceable back to heavy vibration during machining.

Measuring point B: With full engagement of the cutters

The lateral forces that arise during thread milling affect the quality of the thread.

GARANT Master TM cutters have a clear distribution of the measurement points. Conventional thread milling cutters tend to generate high levels of vibration, causing significantly uneven distribution of the bending moment. To some extent this leads to threads no longer true to gauge.

To the contact

To the contact